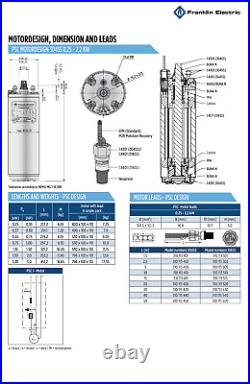

SUBMERSIBLE WELL MOTOR 4 230V 0.75kW 1.0HP FRANKLIN ELECTRIC. 4″ stainless steel (304SS) motors are manufactured to ISO 9001 for use in water wells 4″ or larger. The engine does not require any maintenance. The engine is filled with a special FES93 antifreeze liquid. A special diaphragm compensates for pressure losses inside the engine. 4 NEMA mounting construction with studs. Stainless steel shaft. Stainless steel 316SS stator body. Engine is factory filled with non-toxic, water-soluble Franklin filling solution. StatorSHIELD T – Franklin sealing system with hermetic windings. Fluid lubricated radial bearings. Heavy duty Kingsbury bearing, 100% maintenance free. Field replaceable cable using exclusive Franklin Water Bloc technology with extended stainless steel locking nut. High efficiency electrical design for low operating costs. Drinking water certificate. Suitable for use in water with increased salinity. Electrical equipment: 1 PSC / 2-wire 1 / 3-wire 1 / 3. Maximum storage temperature: -15°C – + 50°C. All engines are manufactured in ISO 9001 certified factories and 100% tested. Standard single-phase stainless steel motor (0.75kW 1.0HP). Power: 0.75kW. Frequency: 50 Hz. Axial load: 4 kN. Protection class: IP 68. Insulation class: B. 4 NEMA compliant flange. Nominal medium temperature: 30°C with a cooling flow of 0.08 m/s. Number of activations in 1 hour. 20 with a minimum break of 3 min. Mounting position: vertical or horizontal (shaft end elevated). Voltage tolerance: -10% / +6% (50 Hz). Direction of rotation – counterclockwise as viewed from the end of the shaft. Supplied with a cable (1.5/2.5 m).